Introduction

In this article we will outline how to conduct the hazard assessment in a food plant.

Step 1: Understanding the prerequisites of Hazard Assessment.

Before we conduct a hazard assessment, we need to identify the regulations and standard applicable to the business.

If assistance is needed, you are recommended to look for Food Safety Consultant.

Step 2: Conducting a hazard analysis.

Of course, each food product has its own characteristics in terms of hazard relevancy.

To illustrate the latter, we will consider the following 3 examples:

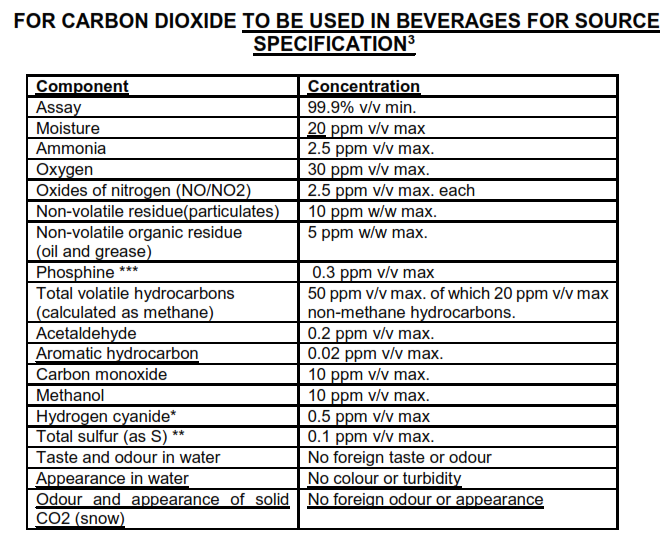

Beverage Carbon dioxide as ingredient for beverage bottlers

For Beverage grade carbon dioxide, physical and biological contamination is quite irrelevant during a hazard analysis. The removal of chemical impurities through process steps should be addressed.

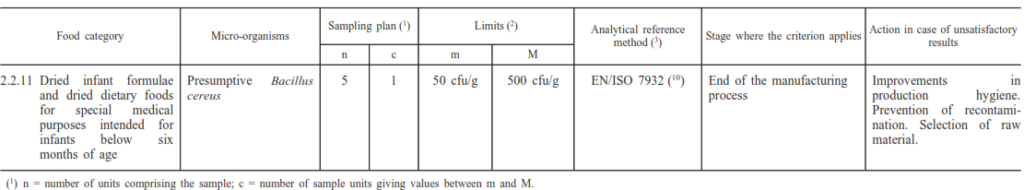

Raw sugar destined as consumer goods products.

For raw sugar, the natural cross contamination would be chemical contamination. The hygroscopic nature of the raw sugar would deter any microbial activity except for mold or sporulated bacteria.

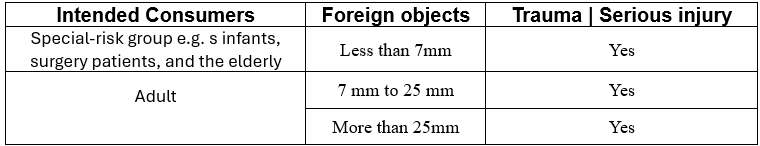

Mass catering destined for consumers

For any restaurants, the hazard analysis would include the biological, chemical and physical hazards. You would list down all applicable hazards based on your end product(s). Of course, you would be recommended to use the process flow as the main backend skeleton to ensure that no step is missed.

Step 3: Control measures & Limits

You will describe all the control measures which have been taken to circumvent or decrease the risk of cross contamination:

- Product Description Sheet

- Technological process step (Cooking, Pasteurisation, metal detection, vacuum packaging, aluminium foil sealing.)

- Prerequisite program (Cleaning SOPs, Calibration procedure)

- Outsourced program (Pest Management Services…)

- Legal or Industry best practices or customer requirements.

Chemical limits

Fig1: Excerpt from EIGA public document

Click here to download the EIGA best practices.

Biological limits

Fig 2 : Excerpt of microbial limits as per EU Reg 2073 / 2005

Click here to download the EU Regulation 2073 /2005.

Physical limits

Table 1: Criteria for which sharp foreign objects can cause trauma or injury if ingested

Click here to download CPG Sec. 555.425 Foods, Adulteration Involving hard or Sharp Foreign Objects

Step 4: Hazard Assessment Method

After the hazard analysis, you would use the prescribed method to perform Hazard Assessment. The prescribed method would depend on the standard you are using to develop the food safety system.

Examples of methods would include Food Codex Decision tree, Hazard Rating Number or Customer Decision Tree.

As a matter of fact, step 4 is probably the trickiest part. If the team incorrectly identify the CCPs for the sake of food safety, the outcome can drive a company out of business.

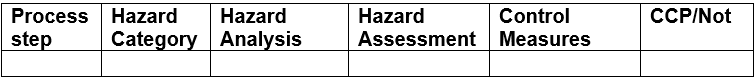

As a rule of thumb, you will categorize a step as a CCP if the step fails to address the following limits through the deployed control measure. You can use the following template to conduct the hazard assessment.

Table 2: Template for an Hazard Analysis guideline

Step 5: HACCP plan

The output of the hazard assessment is the HACCP plan. You will use the latter to ensure that the defined limits are not exceeded.

In isolated cases, the corrections and corrective actions defined in the HACCP plan shall be deployed when the defined limits are not complied with.

Summary

Once the HACCP plan has been performed, you will review the whole exercise at least once a year or when there has been a significant change within the system.

FAQ

Who is responsible to conduct the hazard assessment?

It is the food safety team who will do the exercise. In practice, there will be 2-3 champions in the group who will undertake the initial draft, after which the latter will be validated by the food safety team.

Is it normal for not having a critical control point?

Yes, in certain cases we can have no critical control points.