I. Audit findings

A. Definition and Types of Audit findings

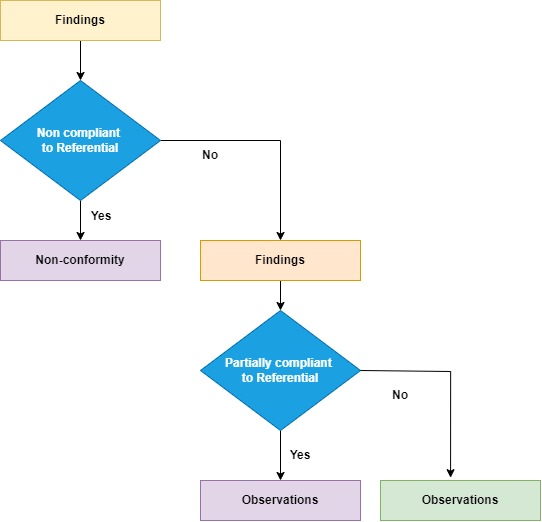

Looking how to handle food audit finding, please look no further. During the closing meeting the auditor normally discusses his findings with the auditee. These findings are then categorized according to the decision tree, as per below.

Fig 1: Decision tree to classify audit findings.

- Positive findings are highlighted food safety areas where the business is doing well.

- Non-conformity are important opportunities to improve a HACCP system.

- Opportunities for improvement, are observations noted which can strengthen the food safety program.

B. Template to manage non-conformity.

A referential can be a regulatory framework, a food safety standard or customer audit framework. In this article, we provide a handy template to manage the non-conformity through a simple template. You can download the template here.

II. Common Causes of Audit non-conformities

From our experience, we have enumerated the following non-exhaustive list as the most common causes of non-conformities:

- Inadequate understanding of HACCP plans or a failure to follow the instructions.

- Improper management of sanitary control. We would include personal hygiene, bad cleaning practices as well as failure to address pest infestation.

- Temperature control issues. This include improper storage temperatures and inadequate temperature monitoring of process steps.

- Lack of traceability of products. This corresponds to difficulty to identify the products as well as failure to recall contaminated food in a timely manner.

- Inaccurate, incomplete, or outdated documentation leading to confusion.

III. Audit finding management

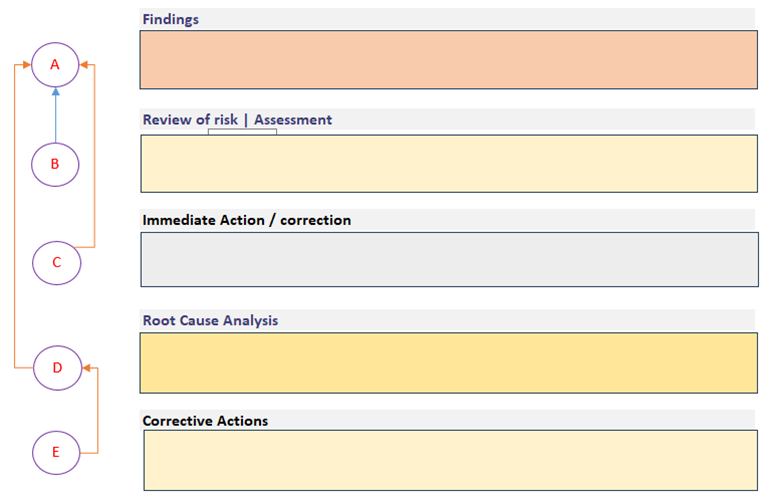

After having reviewed the main food standards requirements, we have built the following skeleton to have all the non-conformity compliance details.

Fig. 2: Features of an non-conformity follow-up

- The (A) part consists of the finding which deviate from the food safety standard. It should be described as is from the audit report.

- The (B) part consists of the immediate action which would stop the deviation from occurring within the food safety system. Any consequence for which affected products have been the outcome needs to be identified, isolated, and addressed as relevant (recall, withdrawal, rework or product discard)

- The (C) part is the step whereby the deviation is assessed in terms of implications, whether it is an isolated case, or it is repeatable, on which process, how the control measures have circumvent any food hazard describe so that the necessary resource is being addressed. This can include putting future preventive actions such as modifying the procedure, or create a risk register for better monitoring….

- The (D) part is the step whereby the deviation is being analyzed in terms of root causes of the finding (A). Various methods such as the 5 whys or the on 5M provides precious insights to identify the causes.

- The (E) part is the step whereby the corrective actions are described to address the root cause(s).

C. Summary

Resolving audit discrepancies is critical for maintaining transparency and accuracy in business operations. By using the method in this article, we can improve the overall performance of our HACCP system.